Dahlander motors—also known as two-speed motors—are an often overlooked solution for changing motor speed without advanced electronics. Even though they’ve been around for decades, many electricians and engineers either misunderstand them or don’t realize how powerful they can be when applied correctly.

In this article, you’ll learn what a Dahlander motor is, how it achieves two speeds, how to wire it in both delta and double star configurations, and why it’s no longer the most efficient choice in modern systems.

Understanding the Dahlander Motor

A Two-Speed Induction Motor

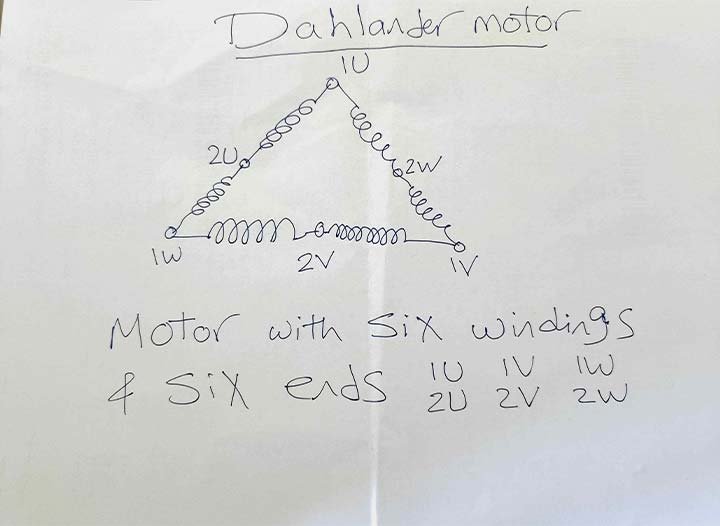

A Dahlander motor is a special type of three-phase induction motor that allows two distinct speeds using a single winding with different pole configurations. It’s designed with six terminals instead of three:

- U1, V1, W1

- U2, V2, W2

These terminals represent the start and end points of three winding coils inside the stator. By changing how these windings are connected, you effectively change the number of magnetic poles, which in turn changes the motor speed.

The Synchronous Speed Formula

To understand how the speed changes, recall the basic synchronous speed formula:

Ns = (120 × f) / P

Where:

- Ns is the synchronous speed in RPM

- f is the supply frequency in Hz

- P is the number of poles

So:

- More poles = lower speed

- Fewer poles = higher speed

Real-Life Example: Dahlander Motor Speeds

Let’s say the motor nameplate shows two speeds:

- High speed (double star): 1,466 RPM

- Low speed (delta): 741 RPM

These values closely match the theoretical speeds of 1,500 RPM (4 poles) and 750 RPM (8 poles), accounting for slip.

Wiring a Dahlander Motor

Low-Speed Connection: Delta

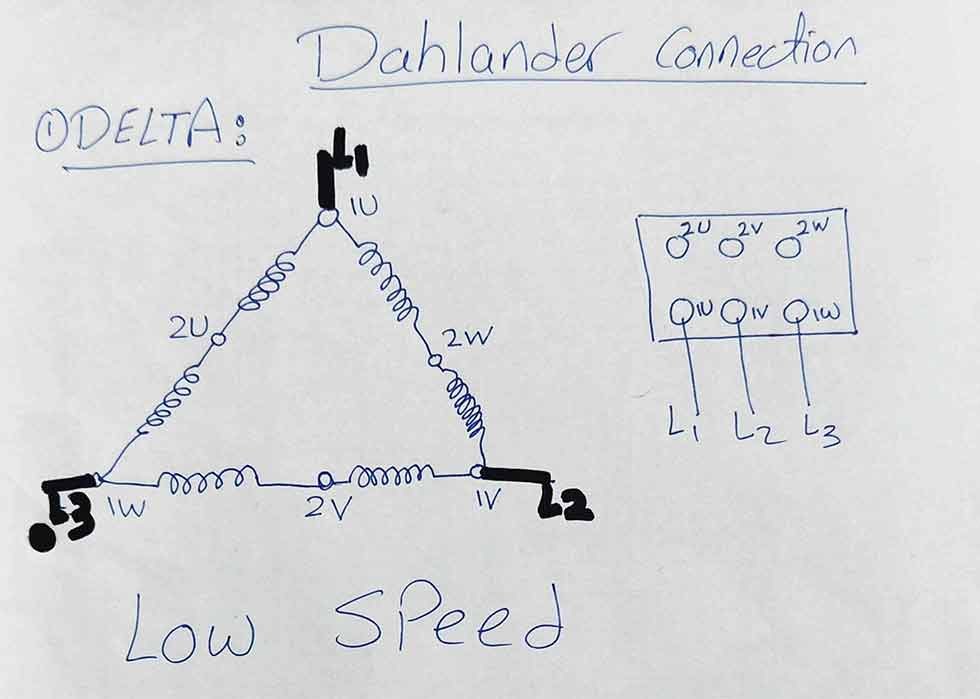

To achieve low speed, use the delta connection:

- Connect L1 to U1, L2 to V1, and L3 to W1

- Internally, each coil pair (U1–U2, V1–V2, W1–W2) is connected in series

- This configuration creates eight magnetic poles

Delta provides slower motor speed but comes with trade-offs in efficiency.

High-Speed Connection: Double Star

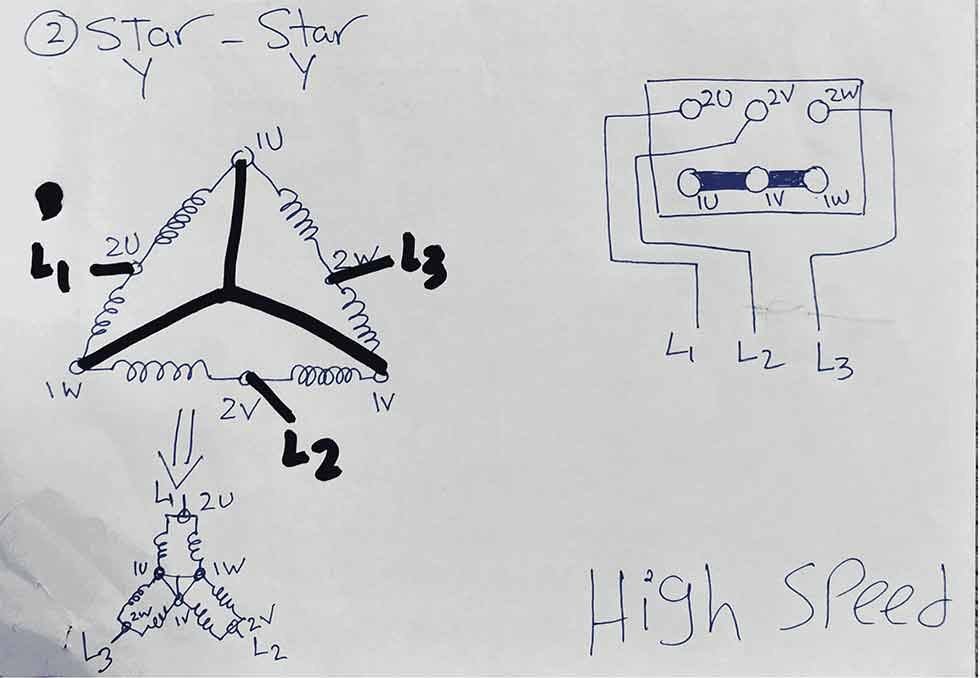

To achieve high speed, use the double star connection:

- Connect L1 to U2, L2 to V2, and L3 to W2

- Join U1, V1, and W1 together at a single neutral point

- This creates two parallel star-configured windings, resulting in four poles

This setup gives you higher motor speed with better performance.

Visualizing the Connections

Inside the terminal box, the wiring differences are visually distinct:

- Delta: Three separate paths feed each winding group independently

- Double Star: The three windings converge into a single neutral point

Understanding these visual cues can help with quick identification during wiring or maintenance.

Why Delta Isn’t Ideal Anymore

While the delta configuration enables low-speed operation, it comes with performance drawbacks:

- Lower efficiency

- Lower power factor

- Reduced mechanical output

Even though the current draw remains the same as in double star, the mechanical power delivered is significantly lower, making delta a poor choice for continuous operation.

The Modern Alternative: Variable Speed Drives (VSDs)

Today, most systems use standard induction motors paired with VSDs (Variable Speed Drives). These drives allow:

- Seamless speed control

- Higher efficiency

- Better motor protection

- Smooth start/stop behavior

Unlike Dahlander motors, VSDs don’t require rewiring to change speed, making them the preferred option in new installations.

When Are Dahlander Motors Still Useful?

Despite their limitations, Dahlander motors are still found in:

- Legacy industrial setups

- Simple machines with fixed two-speed needs

- Budget-sensitive applications where electronics aren’t viable

Understanding how to work with them is still valuable for electricians and maintenance engineers.

Final Thoughts

Dahlander motors are a brilliant example of electromechanical ingenuity. By reconfiguring internal winding connections, you can double the number of poles and achieve two distinct speeds without a VSD. However, as electrical systems evolve, efficiency and flexibility make VSDs a smarter long-term solution