When it comes to high voltage circuit breakers—critical components in today’s electrical power systems—the selection of the insulating and arc-quenching medium is crucial. Among the available options, sulfur hexafluoride (SF₆) has emerged as the dominant choice. But why is SF₆ favored over other gases or technologies?

Let’s explore the key reasons why SF₆ is used in high voltage circuit breakers, along with how it works in real applications.

1. Outstanding Insulating Properties

SF₆ is renowned for its exceptional dielectric strength, which is 2.5 to 3 times higher than air. This allows circuit breakers filled with SF₆ to withstand higher voltages in more compact spaces, reducing the physical size of the equipment.

- Dielectric strength increases with pressure, and SF₆ maintains stability even under high-voltage stress.

- This is particularly valuable in dense switchgear arrangements and urban substations where space is limited.

2. Superior Arc Quenching Capability

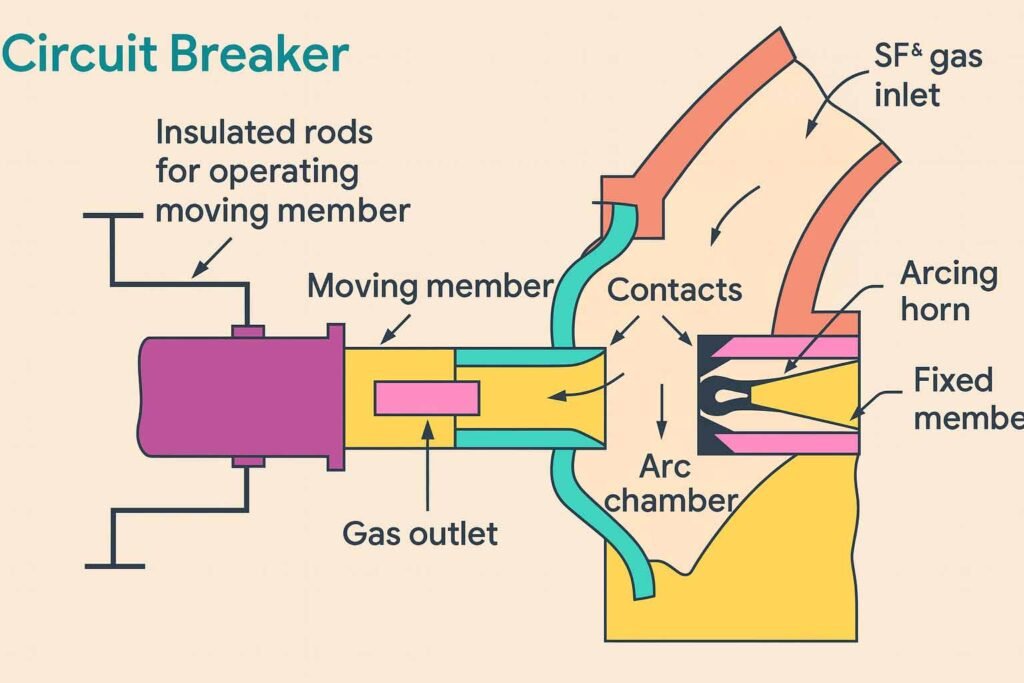

A fault or switching operation generates an arc between the circuit breaker’s contacts. SF₆ is highly effective in extinguishing this arc due to its electronegative nature—meaning it absorbs free electrons that would otherwise sustain the arc.

- In the SF₆ circuit breaker, gas is blasted through a nozzle directly onto the arc.

- The gas quenches the arc by de-ionizing the region between contacts, and at the next current zero, the arc naturally extinguishes.

This makes SF₆ circuit breakers extremely reliable, especially when dealing with high fault currents and fast switching requirements.

3. Thermal Stability & Cooling Effect

SF₆ is thermally stable up to 500°C and has excellent heat transfer characteristics. This helps it:

- Remain stable during arcing events.

- Cool the arc plasma rapidly, preventing damage to internal parts and increasing equipment lifespan.

4. Chemical Inertness

SF₆ is non-reactive and non-corrosive. It does not degrade most materials used in circuit breakers, contributing to:

- Minimal aging of internal components.

- Long operational lifespans of 30 years or more in many designs.

5. High Gas Density

Its high molecular weight results in a dense gas, making it an excellent insulator that prevents ionization and dielectric breakdown. This is especially beneficial in compact breaker designs used in gas-insulated switchgear (GIS).

6. Self-Healing Properties

When subjected to high-energy arcs, SF₆ may decompose. However, its decomposition products often recombine to form SF₆ again, restoring its insulating properties over time. This self-healing characteristic extends service intervals and improves long-term reliability.

7. Non-Flammable and Safe

SF₆ is inert and non-flammable, which adds a layer of safety, especially in enclosed substations or indoor applications. Unlike oil-filled breakers, there’s no fire risk associated with SF₆ during fault interruption.

8. Automation and Fast Operation

Modern SF₆ breakers work with high-speed mechanical drives and relay-controlled systems. When a fault is detected:

- A spring-loaded mechanical latch is triggered by a relay.

- The breaker opens, and pressurized SF₆ gas is directed through the contact assembly, rapidly extinguishing the arc.

This ensures a safe and instantaneous disconnection, preventing transformer damage or system instability.

Environmental Considerations

Despite all its benefits, SF₆ has one major downside:

It is a potent greenhouse gas, with a global warming potential (GWP) over 23,000 times greater than CO₂ over a 100-year period.

To address this:

- Manufacturers and utilities are investing in SF₆-free alternatives such as vacuum or dry air technologies.

- Monitoring systems, gas recycling, and leakage prevention are now standard in SF₆ installations.

While vacuum circuit breakers are becoming popular, especially at medium voltage levels, SF₆ still dominates the high voltage and extra-high voltage range due to unmatched performance.

Summary: How SF₆ Circuit Breaker Works

To wrap up, here’s a simplified sequence of how an SF₆ circuit breaker operates:

- Normal operation: Current flows through the main contacts in a closed state.

- Fault detection: A relay senses the abnormal condition and signals the breaker to trip.

- Contact separation: The main and arcing contacts open. An arc forms between the arcing contacts.

- Arc quenching: Pressurized SF₆ gas flows through a nozzle, removing free electrons and extinguishing the arc at the next current zero.

- System isolation: The circuit is safely interrupted, and components are protected from damage.

Conclusion

SF₆ is not just a gas—it’s a technology enabler. Its unique combination of electrical, thermal, and chemical properties makes it indispensable in high voltage circuit breakers. Though its environmental impact is significant, ongoing innovations are working toward a future of sustainable and SF₆-free switchgear.

Until then, SF₆ remains the gold standard in the high voltage world—reliably powering our grids and protecting our infrastructure.